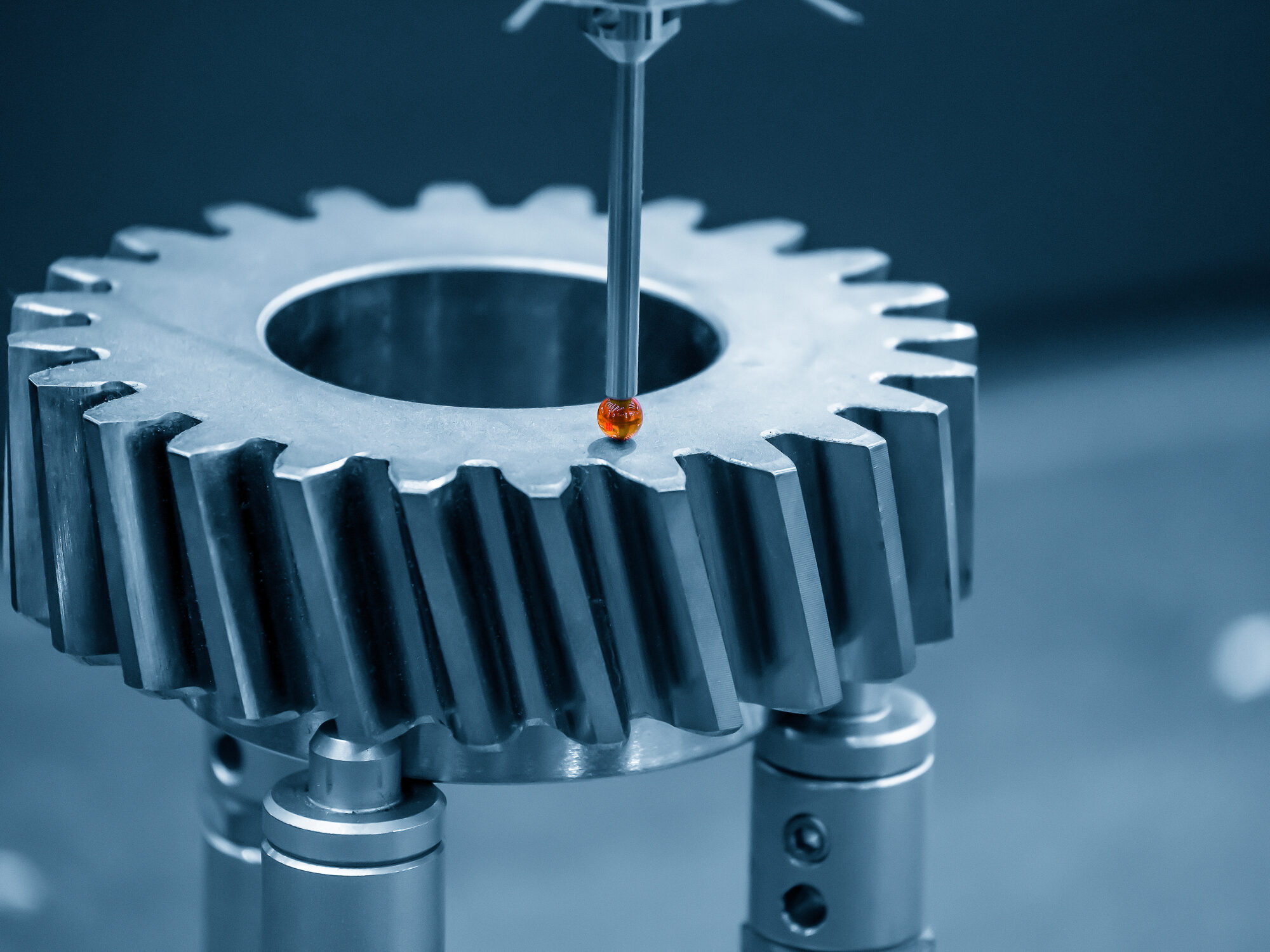

High volume, High Pressure

ERP for contract manufacturing

In high-volume contract manufacturing and electronics manufacturing services, timing is critical. Expandable ERP’s powerful Material Requirements Planning (MRP) engine ensures timely procurement and production, aligning operations with client demands.

Build for trust

Chosen by Leaders – Our Customers:

Mixed Mode

Multiple Manufacturing Modes

The best contract manufacturers are able to manage multiple customer requirements simultaneously, including products they build through a combination of discrete, batch process, and mixed-mode manufacturing processes.

Maintaining low production costs and high quality standards while meeting aggressive delivery commitments takes special skills and the right business software.

Driving Go To Market Efficiency

Highly Automated Integrated Tools

Expandable ERP includes integrated tools that support contract manufacturers and EMS providers who operate highly automated processes.

- Multi-level bill of materials

- Revision level tracking

- Convert quote to sales order

- Engineering change order tracking

- Strong inventory management

- Shop Floor Mobility

- Bi-directional lot tracking

- Expiration date tracking

- Lot control and serial number tracking

- EDI transmissions

- Bar-coding

- Labot tracking

Protect Your Go-To-Market

Applying Economies of Scale

Contract manufacturers and EMS companies operate best in a highly automated environment and Expandable ERP can help.

Reliable tools to handle a demanding production environment

Juggle a range of customer requirements that could involve a combination of discrete, batch process, and mixed-mode manufacturing processes.

Versatile manufacturing system to serve a wide variety of customers

Delight multiple customers simultaneously while meeting delivery dates, product design requirements, and quality specifications.

Detailed inventory management to control supplies

With multiple storerooms and multiple locations within a store room, you’ll find many creative ways to manage your customer inventory.

The medical device industry is heading toward $800 billion by the end of this decade. But here’s what that growth means for manufacturers: medical device companies typically maintain …

Read More