It seems like everyone has a story (or two) about their ERP system – some good, some not so great. Whether you’re in the middle of an implementation, optimizing what you already have, or just trying to make it all run a little smoother, there’s always something to talk about.

- What are companies really saying about their ERP implementations?

- Why do some of them miss the mark – or get a bad rap?

- How can we make the most of the systems we already have to deliver real value for the business?

- And most importantly, how do we change the game to make ERP a true win?

On November 20, 2025, the new Sip Club, hosted by Expandable Software, MIE Solutions and the Mirador Software Group, was pleased to welcome Peter Adams, Vice President of Business Strategy at BACS, as the featured speaker at the Sip Club to share his experience, insights and solutions on this topic.

What are the common characteristics of really poorly operating ERP’s?

In order to understand what enables a Company to operate an efficient ERP, sometimes it is easier to define what a really poor system looks like. Common characteristics of poor systems we see include

- The Staff has no confidence in the system

- The Staff doesn’t use the system/worked around it and outside it

- Too much reliance on spreadsheets

- Poor business processes

- Poor data quality

- Manual integration of basic applications

- Multiple systems doing the same thing getting different answers

These are all symptoms of a disaffected Team – not engaged, not aligned, and not committed.

ERP as a Strategic Resource

Have you seen a business strategy that wants to know less about how the business is functioning, doesn’t care how they do what they do, doesn’t need to report financials to someone (IRS, Board, Auditors), or doesn’t want to compare themselves to other industry players? Of course not!

Those are exactly the reasons ERP exists and what it should solve for you.

- ERPs come in many flavors; you need to make sure you get one that generally matches your business structure and operations. A bit of a secret here – most if not all ERP solutions will meet the financial requirements, but only a few will match your operational structure or strategy.

- ERP enforces processes, and data is the result.

The goal, then, is to select an ERP system that meets the operational process requirements of your business and can hold the data elements you want to report/analyze.

- If you are a manufacturer, but all manufacturing is outsourced, you might not actually need an MRP-heavy ERP system. You might actually align more naturally with a Distribution-oriented system.

- On the other hand, the reverse is equally true. If you do manufacture or assemble in-house, then you might value the MRP functions within an ERP and select an ERP accordingly.

The point here is that there is a business strategy element to ERP, it isn’t one-size fits all or just go buy one that worked for some other company.

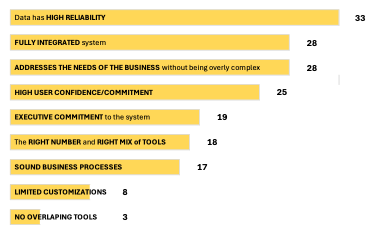

User Feedback

We asked our Sip Club participants regardless of the system used, what are the characteristics of the best ERP’s you have experienced? The responses were as follows:

Other responses included

- Intuitive – easy to train new users on

- Having ongoing user training, remote or user conferences with breakout sessions to address how system handles business is very helpful

- Consistent architecture within the software

- Ability to modify reports easily to tailor the Company’s KPI’s and daily production, including managing Operations

- Visualization of the data

- Easy integration with other tools such as automation and reporting

- Ease of report customization to develop tools for business use

Overcoming Real-World Hurdles: Insights from the Trenches

While frameworks and theories are essential, the real work happens when the rubber meets the road. During the Sip Club session, participants and experts engaged in a candid dialogue about the friction points that inevitably arise during ERP adoption.

We have grouped their feedback and questions into four key areas: The ROI Mindset, Process Alignment, Data Integrity, and Re-implementation Strategies.

1. The ROI Mindset: Moving Past the Sticker Shock

For many organizations, the initial barrier is simply the commitment to invest. One participant, Sean D, shared his experience across the spectrum of business sizes:

“I’ve experienced ERPs anywhere from a startup to the enterprise level… The upfront cost may be daunting, but the ROI speaks for itself with keeping your data intact, secure and with more accuracy. Manual data can always experience ‘human error’… ERP implementations or migrations can be scary, but trust me, it will pay off in the end.”

2. Process Alignment: Don’t Pave the Cow Path

A recurring theme was the tension between existing business habits and software capabilities. Paul S emphasized that software cannot fix a broken process:

“Choosing the right ERP is essential, but establishing strong, well-defined processes first is critical to ensuring successful implementation.”

But what happens when the software feels restrictive? One user asked:

“What do you do when your ERP constrains you to a specific process? It’s easy to blue-sky a process, but I often find my ERP doesn’t support [what I want].”

The answer is two-fold. First, deep due diligence during selection is required to ensure the system generally matches your business structure. However, the second answer requires self-reflection: If a leading ERP solution supports a large customer base with a standard process, why do you need to do something different?. You must ask yourself: Are you really unique, or are you just stuck in “what you’ve always done”?.

3. Data Integrity: The “Garbage In, Garbage Out” Reality

Data quality creates the most visible symptoms of a failing ERP. Karen W put it bluntly:

“Clean your data prior to input into a new system. Garbage In = Garbage out. Don’t try to recreate your current system in your new system.”

This challenge often manifests in specific operational headaches. One participant asked:

“What would you say to a company who has negative quantity on hand on various parts every single day, and sells parts that are flagged as Obsolete regularly too?”

This is not uncommon, but it requires immediate triage. The recommended approach is:

- Stop the bleeding: Implement robust cycle counting immediately to eliminate negative balances.

- Find the root cause: Investigate why these balances occur—whether it is a lack of training, process gaps, or personnel issues.

- Automate controls: Implement alert systems for obsolete parts and physically segregate obsolete inventory in the system so it cannot be shipped.

If you are unsure where to start, getting an experienced set of “outside eyes” to help audit your data integrity is often the best first step. Start by scrubbing your Master Data Files (Customer, Vendor, Item Masters, BOMs) and performing a pareto analysis on your errors to tackle the biggest issues first.

4. The “Re-Implementation”: Fixing a Stalled System

Industry data suggests that the average utilization of ERP capabilities is only 31%. Many companies simply run out of energy after the initial go-live. One user presented a common scenario:

“We are in a position where our ERP implementation set it up as an offline database. We would like to utilize our systems more… How should we go about re-implementing an ERP system into an already existing ERP system?”

Trying to “remodel” a live database is risky—it is like trying to repair an engine while the plane is flying. A common, effective strategy is to set up a clean, new database. This allows you to scrub your Master Data, upgrade software, and refine processes in a safe environment before transitioning over.

The Path Forward: Building Value Brick by Brick

As Hadrian said regarding rebuilding Rome, “Brick by brick, my citizens, brick by brick”

The goal isn’t installing software. It is achieving the vision of the business through better processes, automation, better data and better analytics. This means that your team must be engaged, aligned, and committed. You can’t hire someone else to implement your ERP, they will implement their ERP, not yours!

Only you can drive the implementation of your ERP for your benefit. The best the rest of us can do is be guides and taskmasters.

Best Practices and Lessons Learned

- Executive and User Commitment are CRITICAL

- Change Management is the key to adoption. It starts at the very beginning and runs PAST go-live. Adoption is everything, don’t miss this critical aspect.Get commitment early and engage the nay-sayers

- Eliminate old systems and crutches – “Burn the ships” “When Cortez reached the new world, he burned his ships. As a result, his men were well-motivated.”

- Address the needs of the business without being overly complex

- Right Number and mix of tools

- Limit Customizations – Ask yourself why you are different than the other 10,000 Customers using the system

- Eliminate overlapping tools – Single source of the Truth

- Select an ERP system that meets the operational process requirements of your business and can hold the data elements you want to report/analyze.

- Make people’s lives and work easier

- Tweak the system to use the language/nomenclature people use in your Company.

- Order the fields on the screens in the way people think about their job.

- Change the colors to reflect the corporate colors/logos.

- Instill High user confidence and commitment in the data generated

- Integrated Solutions

- “Single Source of the Truth”

- Adequate tools supporting solid processes: Adequate tools supporting solid processes generates good data. Great tools with bad processes generate poor data – bad data faster

- Optimize process to eliminate “stupid” processes. If you don’t know which ones are stupid, just ask your people, they always know!

Thanks and credit to Peter Adams and all our Sip Club Participants for their contributions and insights for the Sip Club.

Peter Adams is an accomplished executive who has built and sold multiple businesses. Peter helps business leaders build and run better businesses by combining strategic insight with pragmatic processes to improve productivity and business outcomes and helps generate real value from technology in the areas of leadership, process optimization and automation, reporting, and analytics. https://www.linkedin.com/in/petercadams/

Jeff Osorio is a Consulting CFO with over 30 years of experience in operationally oriented companies ranging from pre-Revenue to $4B with over 40 ERP implementations in his portfolio. He is also an Adjunct Professor in the MBA program of the Leavey School of Business at Santa Clara University. https://www.linkedin.com/in/jeff-osorio-1412181/